Properly insulated walls can greatly enhance your home’s comfort and reduce energy costs. Insulating your walls is a crucial step in the overall process of insulating your home, and there are various materials and methods available to achieve this. In this comprehensive guide, we will explore different forms of wall insulation, factors to contemplate before insulating your walls, and recommendations for accomplishing effective wall insulation. When considering home improvement projects, don’t overlook the importance of professional siding replacement services.

Factors influencing your choice of wall insulation technology

When deciding on the most suitable insulation technology for your home, several factors should influence your choice. It is crucial to consider the thermal performance of the material, ensuring it meets the specific needs of your property. Equally important is the material’s breathability, resistance to moisture, and environmental impact. Additionally, factors such as installation ease, space constraints, and your budget will play a pivotal role. By carefully weighing these considerations, you can select the right insulation, whether it be PIR, insulation slabs, EPS polystyrene boards, fiberglass, or reflective insulation, to enhance your home’s energy efficiency and comfort.

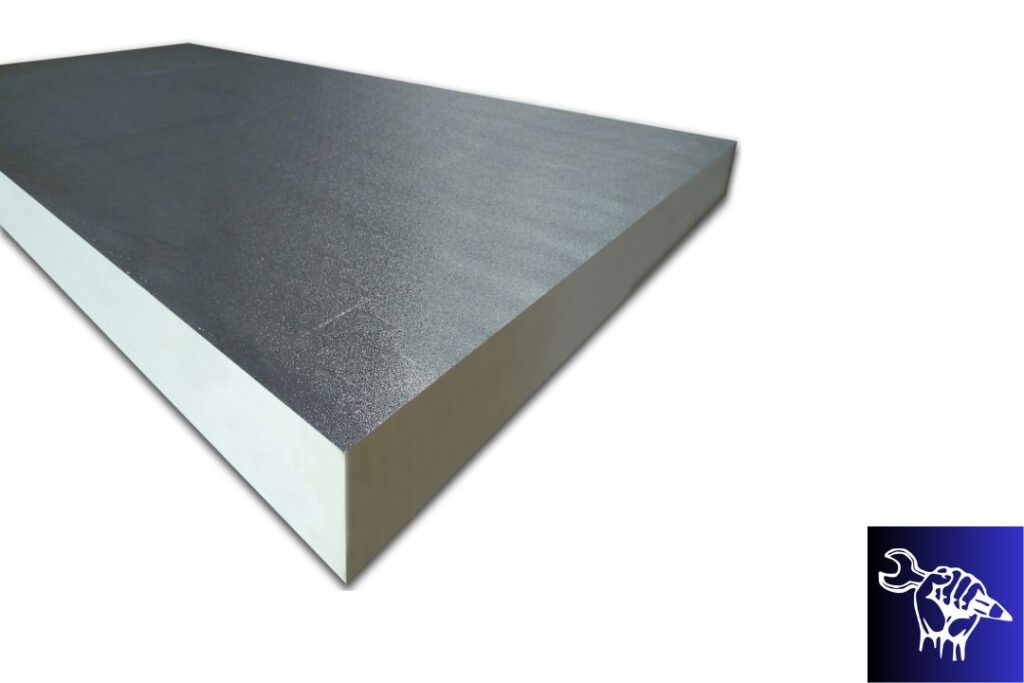

PIR Insulation (polyisocyanurate)

Siding Replacement Services offers PIR Insulation, also known as polyisocyanurate insulation, which is a foam insulation specially designed for insulating walls. This type of insulation provides substantial benefits by effectively reducing heat loss and improving energy efficiency, primarily due to its impressive thermal resistance measured in R-value.

As Wikipedia mensions, PIR insulation consists of rigid foam composed of isocyanurate resin and polyol. It is commonly layered with foil or plastic laminate on one side or both sides, serving the dual purpose of acting as a vapor barrier and enhancing its thermal resistance capabilities. Its lightweight properties, ease of installation (you don’t have to use any specialistic tools), and strong compressive strength make PIR insulation a preferred choice for various commercial and residential construction projects.

Insulation Slabs

Wall insulation slabs, also referred to as batt insulation, are frequently employed as insulation materials in a variety of building components, such as walls, ceilings, and floors. These insulation slabs come in pre-cut dimensions, ensuring they align seamlessly with the typical spaces between wall studs, joists, and rafters. They typically consist of materials like fiberglass insulation and Rockwool insulation.

In today’s environmentally conscious era, eco-friendly insulating materials like Sheepwool, wood fiber, or hemp wool are gaining popularity due to their superior insulation properties, prolonged durability, and their role in promoting healthier living environments. Insulation slabs can be acquired with or without facing materials, such as kraft paper, foil, or non-woven fabric, and these facings serve various purposes, including moisture management, increasing fire resistance, and simplifying the installation process.

Meanwhile, maintaining and repairing your roof is essential to ensure the longevity and structural integrity of your home, and regular roof repair and maintenance service can prevent leaks and water damage, which, in turn, can help preserve the effectiveness of insulation, as a well-maintained roof ensures that insulation remains dry and functional, thereby contributing to maintaining a higher R-value and superior insulation performance.

EPS polystyrene insulation boards

Crafted by expanding and shaping small polystyrene foam beads into large boards. Due to their relatively lower R-value (thermal resistance), these boards are commonly employed in cost-effective insulation applications, such as insulating concrete blocks or beneath concrete slabs. On the other hand, XPS polystyrene insulation boards are formed by extruding and compressing polystyrene foam into board form. Because they offer a higher R-value compared to EPS boards and possess greater resistance to moisture, these boards are a favored choice for external insulation and finishing systems (EIFS) and similar applications.

XPS boards, with their superior R-value and moisture resistance, can help mitigate issues like ice damming by maintaining consistent thermal performance and reducing the risk of ice buildup on roofs during winter months, thereby contributing to improved energy efficiency and structural integrity.

Fibreglass insulation

Fibreglass insulation, commonly referred to as glass wool, occupies the fifth position on our list. This fibrous material, composed of a blend of ingredients bonded using specially engineered resins to maintain its structural integrity, can be applied by blowing it into designated spaces, typically within cavity walls or under-roof areas (as loose-fill insulation), or it can be neatly packed into insulation slabs and rolls for convenient installation on walls or floors.

It’s notable for its non-combustible nature, often making it a preferred choice not only for residential settings but also for commercial and industrial spaces where fire safety is paramount, and its moisture-resistant properties ensure that it remains impervious to moisture absorption, allowing it to naturally dry without compromising its insulation effectiveness. Additionally, with its favorable R-values, it can significantly contribute to energy savings and lower CO2 emissions, making it an eco-conscious choice, much like the roof repair and maintenance services we provide to enhance the overall energy efficiency, longevity, and structural integrity of your property, ensuring a comfortable and sustainable living environment.

Reflective insulation

This type of wall insulation typically incorporates reflective materials, often aluminum, which are adhered to substrates like kraft paper, plastic film, or cardboard. It’s also occasionally applied on the surfaces of specific insulation boards to enhance overall performance. While most insulation products primarily target conductive and convective heat transfer, reflective foil insulation focuses primarily on mitigating radiant heat transfer. It is commonly used in roof insulation, positioned between roof rafters, or placed between floor studs and wall joists.

Unlike the other materials featured on our list, reflective insulation lacks an R-value, and its effectiveness varies depending on factors such as its location within the structure, prevailing weather conditions, and its interaction with other insulation materials.